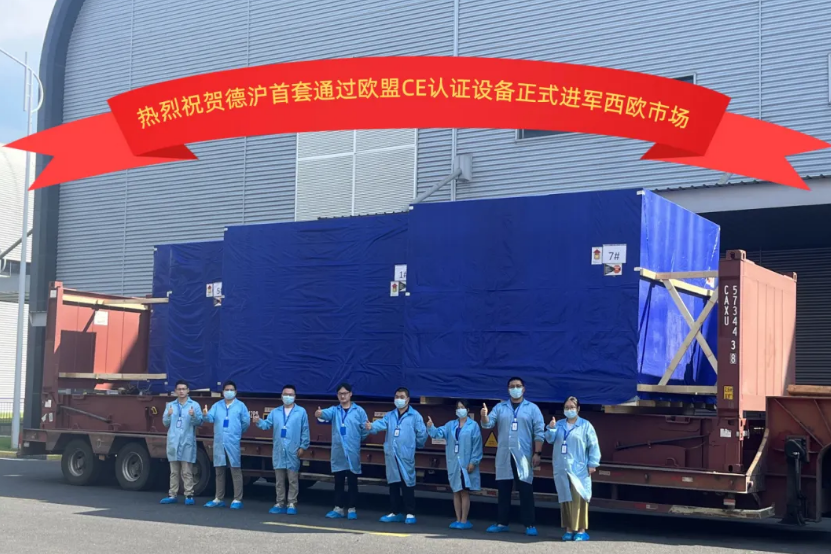

August 21, SPS core equipment sets officially ship to Paris, France.

August 21, the company’s core equipment sets officially shipped to Paris, France, marking another milestone for SPS. Following the significant expansion into the North American market, this first set of CE-certified equipment has now entered Western Europe. The SPS team executed end to end process control with “zero error” standard, with arrival at the client’s site expected by late Sept, immediately carry on installation and commissioning. The International Business Unit, Product center, Manufacturing center, and Supply Chain dept collaboratively delivered this extraordinary achievement.

The core equipment sets represents SPS’s self-developed technology,it makes a major achievement in SPS “high-end equipment globalization strategy.

A distinctive feature of this project lies in the agreement covering broader terms for public client services and joint marketing operations. This will establish a technology demonstration hub for SPS in the heart of Europe, serving a wide range of clients. The International Business Unit will collaborate closely with this strategic client to vigorously promote the industrialization of perovskite technology in Europe.

To meet the stringent requirements of the CE certification, project team members worked collaboratively to complete over 200 compliance driven technical modifications. This effort successfully achieved the dual objectives of maintaining optimal performance “zero loss” and ensuring full compliance.

From restructuring the documentation system to optimizing the supply chain, every step demonstrates SPS’s relentless pursuit of excellence:

01

Technical documentation system

We systematically organized core documents, including equipment technical parameters and safety design drawings, to establish a complete set of technical documentation compliance with EN standards.

02

Supply chain compliance screening

We conducted global compliance screening for critical components, replaced uncertified parts, and adjusted installation processes to ensure every screw and every circuit complies with CE regulations.

03

Design iteration & upgrade

Incorporating feedback from testing agencies, we optimized the electrical layout of the equipment. Ultimately, while ensuring device performance, we achieved end-to-end compliant modifications from component replacement to installation techniques.

As the project leader stated:” CE certification is not merely a procedural “passport” but a practice of integrating international standard thinking from every source of design. Every modification made to comply with standard embodies our confidence in expanding into overseas markets.

The launch of this equipment marks not only a strategic move in SPS’s global expansion, but also a powerful symbol of Chinese high-end manufacturing gaining international recognition. As “Made in China” evolves into “intelligent manufacturing from China”-more advanced, compliant, and innovative. SPS demonstrates through action that true globalization goes beyond mere product export. It is about grounding efforts in technology, embodying standards, and soaring on the wings of quality, ultimately writing a new legend for Chinese brands on the global stage.

SPS was founded by a famous polymer chemist, Dr. Jinshan Wang, who served as the chairman of the board of directors. In just eight years, SPS has grown from a tiny startup transformed into a leading enterprise in slot die precision technology, and now operating three subsidiaries, namely SPS Shanghai, SPS Suzhou. SPS Yangzhou.

SPS was founded by a famous polymer chemist, Dr. Jinshan Wang, who served as the chairman of the board of directors. In just eight years, SPS has grown from a tiny startup transformed into a leading enterprise in slot die precision technology, and now operating three subsidiaries, namely SPS Shanghai, SPS Suzhou. SPS Yangzhou. SPS focuses on the design, development and manufacturing of precision solution film-forming slit coating + vacuum dry baking equipment and its core components, and is the world's leading enterprise in the field of precision solution film-forming equipment in China.

SPS focuses on the design, development and manufacturing of precision solution film-forming slit coating + vacuum dry baking equipment and its core components, and is the world's leading enterprise in the field of precision solution film-forming equipment in China. SPS focuses on three-piece coating, and at the same time builds a public platform for perovskite research institutes SPRI, which has the functions of proofing, technology development and talent training to promote the rapid development of the industry. The institute plays a key role in the industrialization process and is a process accelerator and industrial amplifier.

SPS focuses on three-piece coating, and at the same time builds a public platform for perovskite research institutes SPRI, which has the functions of proofing, technology development and talent training to promote the rapid development of the industry. The institute plays a key role in the industrialization process and is a process accelerator and industrial amplifier. At SPS, we understand the importance of customer service. We are committed to providing customers with a professional, efficient and satisfaction-oriented service experience. Whether it is product consultation, technical support or after-sales service, we will go all out to ensure that every customer can feel our intentions and professionalism. SPS firmly believes that excellent customer service is the cornerstone of sustainable development of enterprises, and it is also the key to winning the trust and loyalty of customers.

At SPS, we understand the importance of customer service. We are committed to providing customers with a professional, efficient and satisfaction-oriented service experience. Whether it is product consultation, technical support or after-sales service, we will go all out to ensure that every customer can feel our intentions and professionalism. SPS firmly believes that excellent customer service is the cornerstone of sustainable development of enterprises, and it is also the key to winning the trust and loyalty of customers. Whether you have any questions, needs, or suggestions, we look forward to getting in touch with you. Through the "Contact Us" channel, you can easily communicate with us, and we will be happy to provide you with the most timely and professional response. We value every opportunity to communicate with you and believe that through close cooperation between the two sides, we can create a better future together.

Whether you have any questions, needs, or suggestions, we look forward to getting in touch with you. Through the "Contact Us" channel, you can easily communicate with us, and we will be happy to provide you with the most timely and professional response. We value every opportunity to communicate with you and believe that through close cooperation between the two sides, we can create a better future together. SPS "Dynamic Information" column is committed to providing you with the latest tech developments, market trends, industry news and other important information. By surfing our latest news, you will be able to understand our latest achievements, strategic planning and future prospects, and witness the growth and transformation of SPS.

SPS "Dynamic Information" column is committed to providing you with the latest tech developments, market trends, industry news and other important information. By surfing our latest news, you will be able to understand our latest achievements, strategic planning and future prospects, and witness the growth and transformation of SPS.