Advanced semiconductor packaging is one of the two major development directions in modern integrated circuit technology. Its strategic significance is particularly profound for China during this critical period.

In a strategic deployment in 2022, SPS expanded into the advanced semiconductor packaging sector while continuing its efforts in the perovskite field.

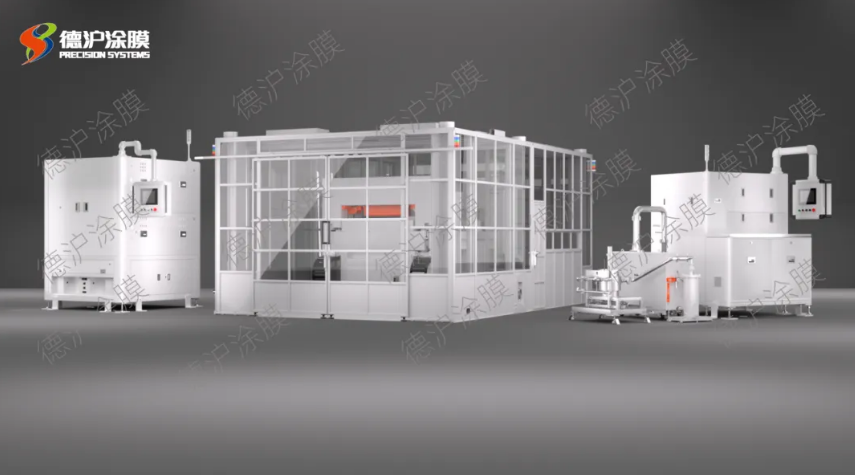

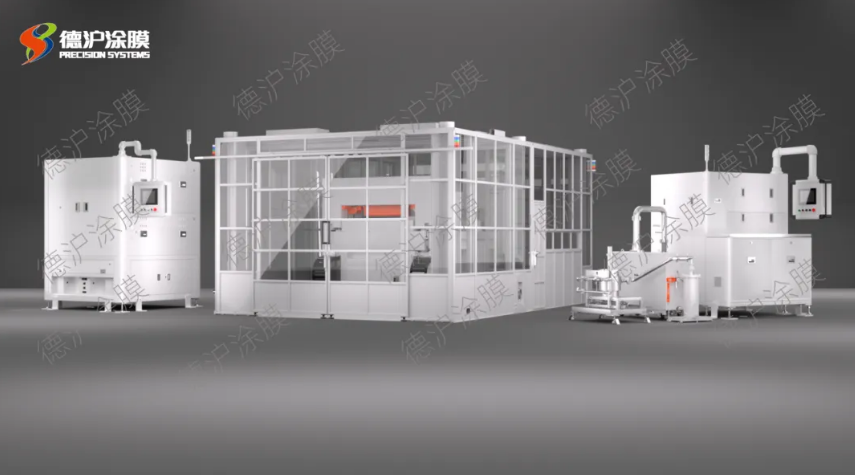

Following last year’s achievement SPS has successfully delivered a second generation PLP coating equipment set for advanced semiconductor packaging, which passed acceptance inspection by a leading domestic semiconductor enterprise and replaced imported alternatives. SPS has now proudly unveiled its third-generation coating, vacuum drying, and annealing integrated equipment for TGV applications. Over the past month, the company has received a continuous stream of customers for sample testing, Those testing resulted in satisfied output.

Compare to perovskite and flat panel display applications, coating equipment for PLP/TGV advanced semiconductor packaging faces significant technical challenges.

Challenge 1: Severe substrate warping across all types of substrates.

Challenge 2: Extreme material viscosity exceeding 10,000 cps.

Challenge 3: Dry coating thickness requirements surpassing 200 µm.

To tackle these challenges, SPS has independently developed multiple world-class, proprietary equipment systems:

Self-developed equipment system

System 1: Dual gantry coater capable of simultaneously applying materials with different viscosities.

System 2: Edge-pressing and vacuum adsorption mechanisms.

System 3: Specialized coating heads designed for ultra-high-viscosity materials.

System 4: One of only two available ultra-large liquid dispensing pumps globally.

System 5: Defoaming system.

All self-developed equipment and components perform at or above international standards. Moreover, in less than two years, SPS has filed over 50 patents in this cutting-edge field of advanced packaging.

To accelerate and sustain its leadership in this new sector, SPS has established an “Integrated Circuit Business Unit” and appointed a senior executive from a top-tier company in the industry to lead it. With this strategic move, SPS aims to become the world’s largest coating equipment supplier in a three year roadmap

SPS was founded by a famous polymer chemist, Dr. Jinshan Wang, who served as the chairman of the board of directors. In just eight years, SPS has grown from a tiny startup transformed into a leading enterprise in slot die precision technology, and now operating three subsidiaries, namely SPS Shanghai, SPS Suzhou. SPS Yangzhou.

SPS was founded by a famous polymer chemist, Dr. Jinshan Wang, who served as the chairman of the board of directors. In just eight years, SPS has grown from a tiny startup transformed into a leading enterprise in slot die precision technology, and now operating three subsidiaries, namely SPS Shanghai, SPS Suzhou. SPS Yangzhou. SPS focuses on the design, development and manufacturing of precision solution film-forming slit coating + vacuum dry baking equipment and its core components, and is the world's leading enterprise in the field of precision solution film-forming equipment in China.

SPS focuses on the design, development and manufacturing of precision solution film-forming slit coating + vacuum dry baking equipment and its core components, and is the world's leading enterprise in the field of precision solution film-forming equipment in China. SPS focuses on three-piece coating, and at the same time builds a public platform for perovskite research institutes SPRI, which has the functions of proofing, technology development and talent training to promote the rapid development of the industry. The institute plays a key role in the industrialization process and is a process accelerator and industrial amplifier.

SPS focuses on three-piece coating, and at the same time builds a public platform for perovskite research institutes SPRI, which has the functions of proofing, technology development and talent training to promote the rapid development of the industry. The institute plays a key role in the industrialization process and is a process accelerator and industrial amplifier. At SPS, we understand the importance of customer service. We are committed to providing customers with a professional, efficient and satisfaction-oriented service experience. Whether it is product consultation, technical support or after-sales service, we will go all out to ensure that every customer can feel our intentions and professionalism. SPS firmly believes that excellent customer service is the cornerstone of sustainable development of enterprises, and it is also the key to winning the trust and loyalty of customers.

At SPS, we understand the importance of customer service. We are committed to providing customers with a professional, efficient and satisfaction-oriented service experience. Whether it is product consultation, technical support or after-sales service, we will go all out to ensure that every customer can feel our intentions and professionalism. SPS firmly believes that excellent customer service is the cornerstone of sustainable development of enterprises, and it is also the key to winning the trust and loyalty of customers. Whether you have any questions, needs, or suggestions, we look forward to getting in touch with you. Through the "Contact Us" channel, you can easily communicate with us, and we will be happy to provide you with the most timely and professional response. We value every opportunity to communicate with you and believe that through close cooperation between the two sides, we can create a better future together.

Whether you have any questions, needs, or suggestions, we look forward to getting in touch with you. Through the "Contact Us" channel, you can easily communicate with us, and we will be happy to provide you with the most timely and professional response. We value every opportunity to communicate with you and believe that through close cooperation between the two sides, we can create a better future together. SPS "Dynamic Information" column is committed to providing you with the latest tech developments, market trends, industry news and other important information. By surfing our latest news, you will be able to understand our latest achievements, strategic planning and future prospects, and witness the growth and transformation of SPS.

SPS "Dynamic Information" column is committed to providing you with the latest tech developments, market trends, industry news and other important information. By surfing our latest news, you will be able to understand our latest achievements, strategic planning and future prospects, and witness the growth and transformation of SPS.